News > KINGWELL News

Offshore Applications

19/04/2016

Wellhead Control Panels – Instrumentation- The wellhead control panel allows the operator to actuate the Valves at the wellheads.

- There are several measuring points piped from the wellhead to the control panel.

- There is a big need for our Valves, Fittings and Tubing.

- Our standard range is made of Stainless Steel 316L.

- Valves which will comply with the NACE specification can be manufactured on request.

Wellhead Control Panels – Pressure test

After the assembly, the unit has to be pressure tested.

This can be realized with:

- water (visual test or pressure drop): pumps

- Air (pressure drop): Air amplifiers

- Gas e.g. Helium (pressure drop or sniffle test): Gas boosters

Wellhead Control Panels - Pressure generation

To operate the Valves at the wellheads, inside or outside of the control panels, air driven pumps are needed to generate the required pressure.

Our PUMPS generate the pressure and hold the pressure without generating heat and without risk of lame or sparks.

Lifeboats

Lifeboats are inflated automatically with gas, when they are in contact with water. The small cylinders are filled with nitrogen or with liquid gas like CO2 or with a mixture of these gases. Within standard periods the pressure and the function of the cylinders have to be tested. In case of pressure drop, the cylinders have to be refilled. The cylinders have to be pressure tested after a certain period of time too according to the nationally valid directives.

Diving

The station is used to fill dive cylinders with oxygen for Closed Circuit Rebreathers up to 300 bar. NITROX gas is very often used for professional diving. Our GAS BOOSTER’s and ROB Series Booster allow to „top up“ Gas cylinders with Nitrogen or Oxygen to create the required mixture.

Bolt tensioning

Hydraulic wrenches or hydraulic nuts are used for bolt tensioning. Our pumps are used to generate the required oil pressure without electric power.

Helicopters

The cylinders to inflate the pop floats have to be tested and recharged regularly. The cylinders to inflate the pop floats have to be tested and recharged regularly.

Diesel Starter

Diesel Engines are often started with compressed air. The required air volume is stored in a 40 bar receiver. MAXIMATOR Air Amplifiers generate the pressure.

Hydraulic Pressure Testing: Leak tests, Burst tests, Pulse tests.

Pressure Gauge Calibrating

Pumps and hydraulic units are used to build up the pressure for gauge calibrating.

Chart Recorder Unit

The chart recorder unit in portable stainless steel frame design is suitable for mobile applications.

Fire Protection Systems

Boosters are used for rapid and precise filling of HALON extinguishers and other fire protection systems.

Fire Protection Equipment Testing

pumps and boosters are used to build up the pressure for hydrostatic tests.

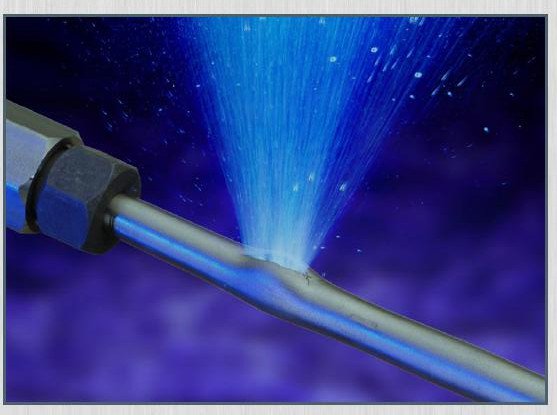

Water fog systems

High pressure water fog systems work in a high pressure range (up to 200 bar) and generate a fog of ultra-small droplets. This is done with big electrical pumps.

Drill Rod Leak Test

boosters generate the test pressure, up to 1,300 bar (18,850 psi) for a Nitrogen/Helium mixture.

Chemical Injection / Metering

Chemicals are metered in all phases of the production, processing, refining, transmission and distribution of oil and gas products.

Wet Sand Blasting

For small particle blasting of metal structures, pipelines, oil platforms and oil rig support vessels.

To prepare the surface for repair, painting, cleaning and rust removal.

Hydraulic line flushing

Pumps generate the pressure to flush hydraulic lines and also to clean the medium after being used.

Electric Circuit Breaker

Air Driven Gas Boosters are used to charge accumulators on circuit breakers with nitrogen or SF6.

Mechanical Seals

Pumps, Amplifiers and Boosters are used as pressure intensifier for mechanical seals.

NACE Booster

Booster can also be driven by sour gas (modification required).

Products

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker