Topics > Latest Valuable Tools

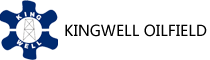

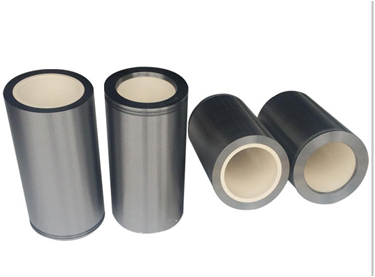

KWOM Series Ceramic Liners

15/07/2016

Ceramic liner is composed of bearing metal sheath and ceramic liner with high wear-resistance, and the integrated cylinder liner is mechanically processed and assembled.

I. Excellent abrasion resistance: There are various sharp particles as lithic quartz sand, iron ore, iron etc., in the high pressure mud during drilling. These particles have high hardness and good abrasion resistance features that will cause grinding and erosion on cylinder surface. Therefore, Cylinder liner materials have higher requirements on abrasion resistance. Compared with the traditional double metal cylinder liner, the life of the ceramic cylinder liner manufactured by the company is improved by more than 10 times and the service life of it is up to 4000-10000 hours.

II. Good surface quality: The surface quality of the ceramic material has a great influence on the service life. The KWOM series ceramic liner prepared by the company has a uniform microstructure and has good smoothness and gloss after being processed many times. Compared with the single phase alumina ceramics, the toughness is improved greatly and abrasion resistance and service life are also improved obviously due to good surface quality and reduction of water for lubrication.

III. Superior comprehensive mechanical properties: KWOM series ceramic cylinder manufactured by the company has features of excellent corrosion resistance, high temperature resistance and abrasion resistance of the ceramic materials and the properties of material strength, hardness, toughness and thermal shock resistance are greatly enhanced based on the phase transformation toughening technology so that it has superior mechanical properties to be suitable for the work in the drilling mud or other corrosive conditions. For example, it could be applied to some areas as hazard drilling environment as deep petroleum storage and geological structure and offshore oil, gas and shale gas exploration.

IV. Lower cost: Compared with the traditional double metal cylinder liner and single phase alumina cylinder, the repair costs, labor costs, the cost of storage and the transportation cost could be reduced and the work efficiency could be improved due to improvement of the comprehensive properties by using the ceramic cylinder liner manufactured by the company.

| Item | KWOM-ZTA Series | KWOM-TZP Series |

| Composition | Aluminum oxide, zirconium oxide, yttrium oxide | Zirconium oxide, yttrium oxide |

| Volume density(g/cm³) | ≥4.25 | ≥6.00 |

| Bending strength(MPa) | ≥560 | ≥800 |

| Fracture toughness(MPa.M1/2) | ≥5.83 | ≥10.00 |

| Rockwell hardness(HRA) | ≥91 | ≥89 |

| Work surface roughness(μm) | ≤0.26 | ≤0.20 |

| Compressive strength(MPa) | ≥3000 | ≥3000 |

| Wear resistance(cm3) | 0.28 | 0.20 |

| Thermal shock resistance | ≥450℃ | ≥450℃ |

| Purchasing Cost | ||||||

|

Continuous working time |

Service life of a liner | Purchasing cost of a linear |

Required quantity |

Total cost | Cost per hour | |

| Double-metal liners | 4000 h | 500 h | 1200 RMB | 8 | 9600 RMB | 2.40 RMB |

| Ceramic liners | 4000 h | ≥4000 h | 5180 RMB | 1 | 5180 RMB | 1.30 RMB |

| Maintenance Costs | ||||||

|

Continuous working time |

Service life of a liner | Replacing times | Replacing cost | Total Cost | Cost per hour | |

| Double-metal liners | 4000 h | 500 h | 8 | 2000 RMB | 16000 RMB | 4.00 RMB |

| Ceramic liners | 4000 h | ≥4000 h | 1 | 2000 RMB | 2000 RMB | 0.5 RMB |

| Brand of mud pump | Types of ceramic cylinder liner | ||||

| BOMCO | F-350/500 | F-800/1000 | F-1300/1600 | F-1600HL | F-2200HL |

| EMSCO | FB-1000 | FB-1300/1600 | F-350/500 | F-650 | F-800/1000 |

| F-1300 | F-1600 | DB-550 | D-300 | D-700 | |

| GARNDER-DENVER | PZ-7 | PZ-8/9 | PZ-10/11 | PZ-L | PA-8 |

| FY-FXD | FO-FXO | FD-FXX | FG-GXG | ||

| NATIONAL | 7-P-50 | 8-P-80 | 9/10-P-100 | 12-P-160 | 14-P-220 |

| OILWELL | A-600-PT | A-850-PT | A-1100-PT | A-1400-PT | A-1700-PT |

| IDECO | T-500 | T-800 | T-1000 | T-1300 | T-1600 |

Products

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker